Flex & Rigid-Flex PCB Assembly

Flex and rigid flex printed circuit boards (PCBs) are used in a wide variety of industries and applications, including medical devices, industrial machinery, lighting, automotive, military, aerospace, defense, consumer products, and down hole drilling.

Our team at CLEAR has extensive experience assembling flex and rigid-flex circuits. We do it all under one roof — including layout and fabrication — which means our engineers are always in constant communication and that we’re able to work out any issues and possible problems before assembly. This not only minimizes any possible project delays, but it also saves our customers time and money.

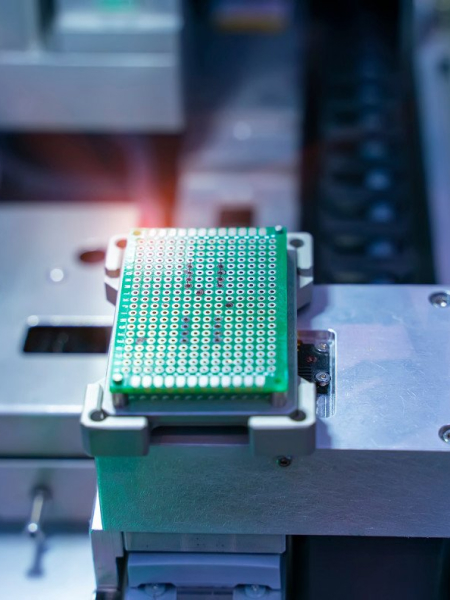

X-ray inspection:

To verify and guarantee precision solder joints — along with other aspects of inspection — CLEAR uses state-of-the-art X-ray equipment that allows for real-time inspection and creates images of PCB inner layers, as well as hidden solder joints beneath component housings. These ultra-high-resolution images and movies are among the best in the industry, with the absolute lowest threshold for radiation. Our X-ray inspection is also used for the verification of ball grid arrays (BGAs) and quad-flat no-leads (QFNs).

Component Procurement

CLEAR offers full turn-key capabilities, which means we will take care of procuring all materials and components. A turn-key solution eliminates delays and allows for peace of mind knowing your PCB is in the hands of our expert engineers from start to finish. We also offer partial and consigned assembly services if you’d prefer to secure the components and materials yourself.

CLEAR’s Assembly Capabilities

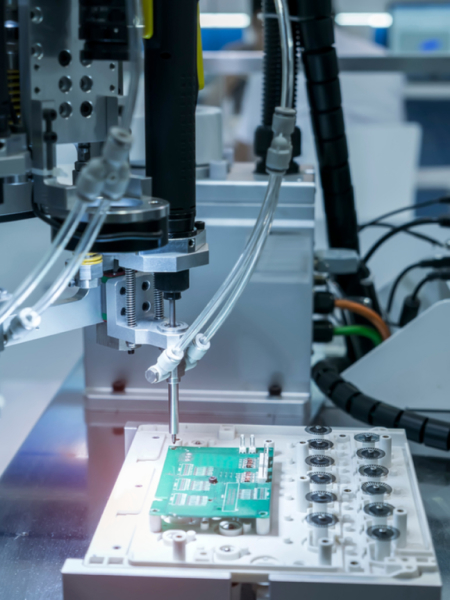

We pride ourselves on the ability to take on complex jobs — from layout to assembly — all under one roof with state-of-the-art technology, including a new selective soldering machine. Our engineering team uses best practices for flex and rigid-flex assembly, and our operators understand how to properly assemble flex circuits to avoid delamination.

- Layout through assembly under one roof

- State-of-the-art technology

- End-to-end expertise

- Specialized in best practices for flex and rigid-flex assembly

- Access to full turnkey, partial, and consigned assembly services

- Short standard lead times and quick turn options

Engineering Expertise & Advanced Technology

We can provide quick turn services because everything is completed under one roof with our own equipment in our state-of-the-art facility. We use the latest technology, software, a secure network, and our own streamlined processes to deliver exactly what you need when you need it.

Our full-service capabilities include:

- An engineering staff with the experience and knowledge to answer all your design and manufacturing questions

- Knowing how to design for manufacturability and the potential cost drivers of a project

- The ability to handle complex jobs

- Certified to work with a variety of industries, including medical, aerospace, and the military

Custom PCB Fabrication, Manufacturing & Assembly

CLEAR has been providing trusted PCB manufacturing and fabrication services since 1980. We differentiate ourselves by being able to take on all complex jobs — all the way from layout through assembly — and we do this under one roof with state-of-the-art technology and equipment. Our experienced engineers have been working with PCB materials for a long time, so we have the vast experience and knowledge to ensure your orders are produced on time and on budget.

We also use a process called concurrent engineering, which means our highly skilled engineers work with clients from the beginning of any project to provide recommendations on materials and design for manufacturability.

CLEAR has the industry leading procedures, facilities, and team to fulfill all your custom PCB manufacturing needs.

Custom PCB Capabilities

Our custom PCB capabilities start with our extensive inventory and state-of-the-art facility located in Silicon Valley. We continue to invest in the most sophisticated production and testing equipment. By keeping exotic materials in stock, we’re ready to go when a custom PCB order comes in — unlike most of our competitors who need to wait for material deliveries.

Our experienced engineers and manufacturing staff have also worked with every type of PCB material, so they have the knowledge and expertise to provide recommendations and answer all your custom PCB questions.

Quick Turns for Custom PCBs

If you have a job that needs to be done in a hurry, look no further than CLEAR. We have impressive quick turn PCB capabilities — including top engineers and state-of-the-art equipment — to meet your tough project deadlines and budgets. We also use InCAM Pro® software to streamline the process, and depending on the complexity of your project, we can provide a quick turn PCB fabrication in as little as 24 hours.

Our quick turn capabilities include:

- 1-5 day turnarounds

- Fully certified defense capabilities

- No outsourcing

- Rapid quoting, order entry, engineering, tooling, fabrication, testing, and shipping

- Total control of build time and product quality

CLEAR is proud to offer our quick turn custom PCB services to all customers, including full certification for defense products.

RF and Microwave PCB Fabrication & Manufacturing

RF Microwave PCB Design & Fabrication Considerations

Material selection is critical and based upon performance requirements. RF microwave PCBs are designed to operate at frequencies, and certain materials are needed to support those frequencies.

In almost every case, the PCB designer will consult with the material manufacturer. Once the materials are selected, the PCB engineer builds the schematic, which refers to the design at the electrical level of the board’s purpose and function.

Our full-service capabilities include:

- Experience and knowledge to answer all your design and manufacturing questions

- Knowing how to design for manufacturability and the potential cost drivers of a project

- Ability to handle complex jobs

- Certified to work with a variety of industries, including medical, aerospace, and the military

We’re also not content with the status quo, which is why we keep up to date on the latest technology and equipment within the industry.

XRAY

To verify and guarantee precision solder joints—along with other aspects of inspection—CLEAR has invested in state-of-the-art X-ray equipment. Our Glenbrook X-RAY System Model 70T allows for real time inspection and creates images of PWB inner layers as well as hidden solder joints beneath component housings. These ultra-high-resolution images and movies are among the best in the industry, with the absolute lowest threshold for radiation.

This kind of monitoring allows CLEAR to become an extension of your organization and helps ensure that we do everything possible to meet or exceed your expectations.

Turnkey

With an all-in-one in-house solution CLEAR International offers the full benefit of a true turn-key solution, eliminating delays and increasing reliable productivity. A fully automated system and ownership of the highest quality equipment available makes our facility capable of even the most complex jobs. Staying technologically advanced and offering the best in systems compatibility allows CLEAR to efficiently offer quality products and the right quick turn solution.